It's been a while that I was thinking about spending a weekend in Amsterdam. And yes, finally, we jumped into our car and drove from Gent to Amsterdam. After checking in Airbnb apartment in the Jordaan district, we headed to visit Thomas Gravemaker from Letterpress Amsterdam.

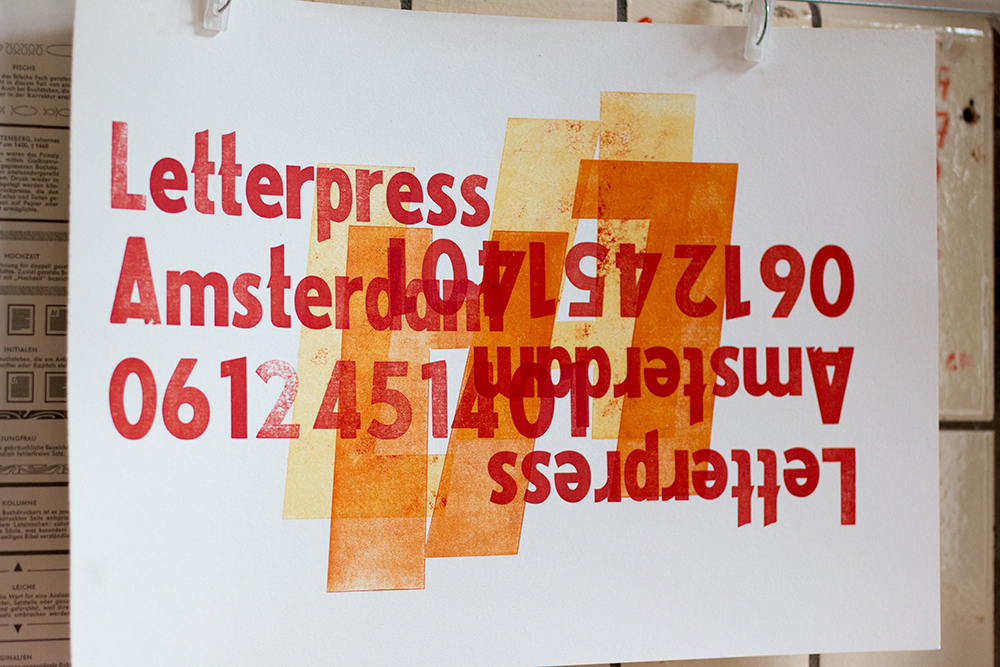

First time I've met Thomas Gravemaker during the Letterpress Workers in Milan a few years ago and we've been in touch ever since (as in fact with all participants). Thomas has an extensive knowledge and experience in letterpress printing and graphic design. He worked for many years in London, Edinburgh and Paris and recently he returned back to Amsterdam to set up a workshop. His work is a combination of new methods with the old ones, creating high standard products, both technically and aesthetically.

Btw, besides teaching various courses at his place Thomas Gravemaker teaches a letterpress course at the MIAT museum once a year, so keep an eye on this space:).

After walking through uncountable amount of bridges (absolutely love the Amsterdam's Bridge Type - Brugletter) we arrived at Thomas' place right in the heart of Amsterdam. The location of Letterpress Amsterdam is quite unique - it is situated in the theater building and Thomas gave us a guided tour through the intricate building constructed from multiple additions build during the centuries. The place was full of costumes, bikes hanging from a ceiling and various objects of the theater company.

The actual workspace is not that big, but it is functional, charming and quite clever organized - almost everything is on wheels.

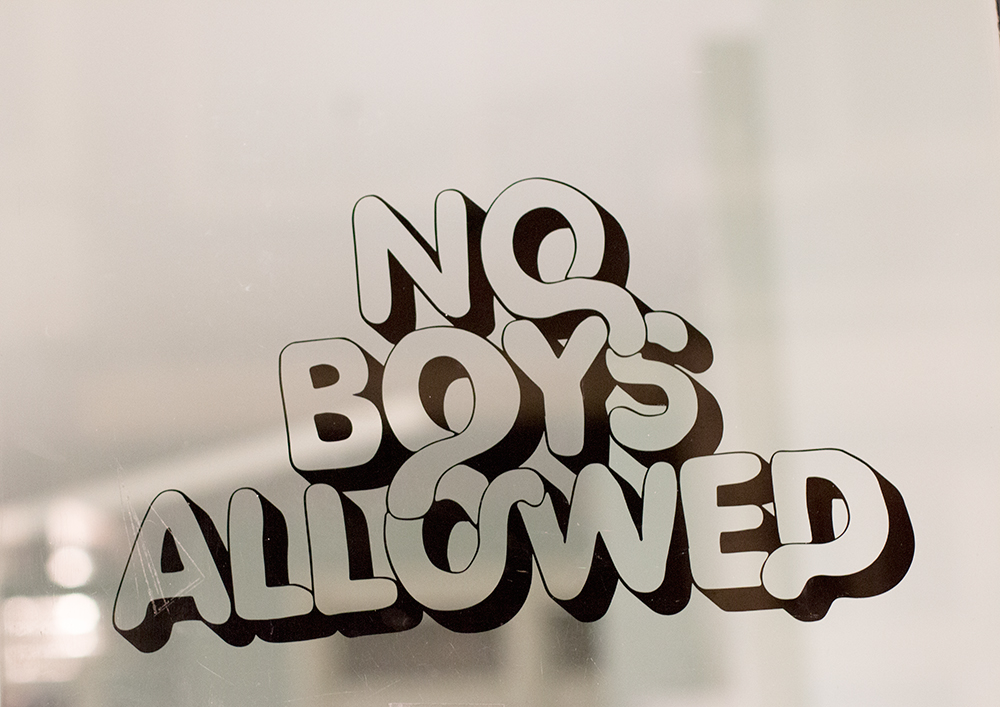

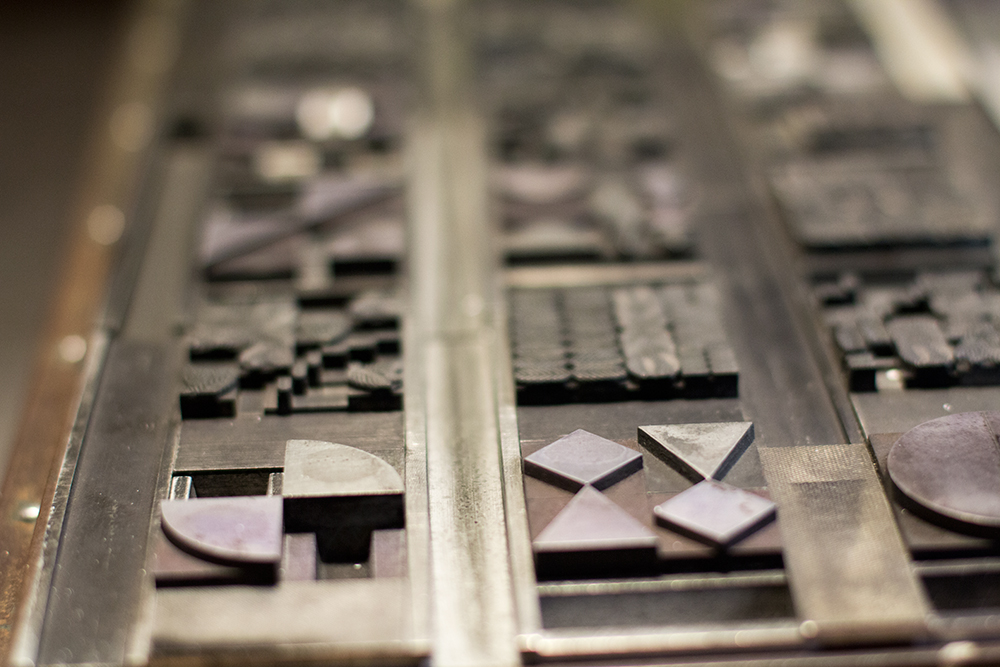

Between a Vandercook, a recently acquired Korrex press and various cabinets filled with metal and wood type, a little box with plastic white & green letters attracted my attention. I knew about Thomas' latest experiments with 3D letters and was curious to see the results. The letters we've been making in Gent a while ago weren't any good due to the surface problem and I'm always interested in possibilities in making new wood type with a reasonable price in order to complete the missing characters or cut the completely new set of letters of a particular size I need.

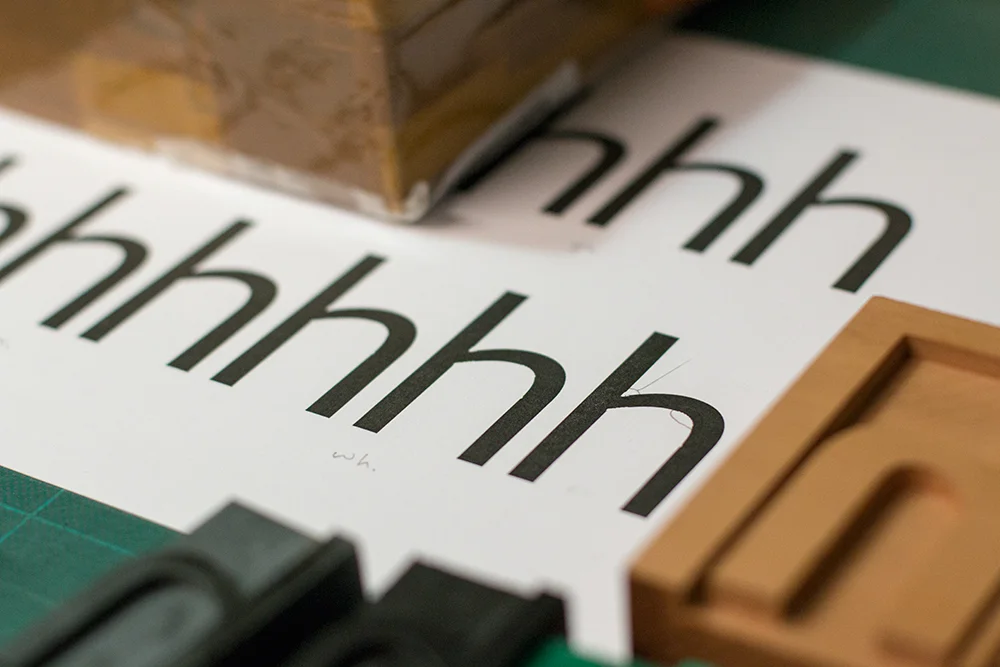

He showed a lowercase 'h', milled from Delrin by a 3D milling machine in Scotland (pictures of the working process). Different quality of plastic has been used and apparently it took around 4 minutes to engrave. Apart from taking the sharp edges of the block, no further finishing was needed. Sounds not bad. Although it didn't perform that good when printing.

Another example in the box were the letters from nylon/Delrin and a wooden letter 'R' where cut by pantograph router by Dafi Kühne. The quality was great, the surface was even, almost no finishing touch was needed and it produced good results when printing and cleaning.

The last examples to compare were the samples cut by CNC router from peach wood by Rutger Paets of the Grafisch Atelier Hilversum (NL). The outlines of the lowercase & uppercase 'h' were sharp and the quality of wood seemed to be resistant to the cleaning solvents used in letterpress printing. At the moment the type Rutger produces has Dutch type heigh only, but I hope he will be making type on French/German height in the near future.

you might also like:

3D printing. MIAT

A2 & New North Press’ 3D-printed letterpress font

Virgin Wood Type

Making new large type for letterpress